What happens to my recycling?

By using your recycling bin correctly, you can reduce the amount of waste going to landfill. But where will your recyclables go instead?

We use recycling contractor Visy Recycling, who collect, sort and process your recyclables, including; cardboard, paper, plastic, steel, aluminium and glass.

Collection

Bayside’s trucks collect your recyclables and head to the sorting facility in Springvale. This facility is called a Material Recovery Facility (MRF).

Sorting

Your recyclables are then put on a conveyer belt for sorting into different recycling categories; paper, cardboard, plastic, steel, aluminium and glass.

It’s a big job and takes a combination of people power, those who manually sort items on a moving conveyer belts, and high-tech sorting machines.

Sorting techniques

Manual pre-sorting

Before your recycling hits the automated sorting machines, pre-sorters pick out any contaminants - items that are not recyclable.

Unfortunately, manual sorters can’t pick out all contamination that doesn’t belong on the fast-moving conveyer belt, which is why it is so important that you sort your recycling at home correctly.

Contaminants include things such as soft plastics, recycling in plastic bags, e-waste, clothing and anything else that does not belong in the recycling bin. These get caught up in the sorting machines and can be dangerous to employees.

Contaminants can also cause recyclable material to be deemed non-recyclable. For example, a few plastic bags mixed into a pile of paper can mean the recycled paper can’t be used to produce new high-quality paper.

Getting to know your recycling will help you to keep the contaminants out of your recycling bin.

Automated machine sorting

At the MRF, machines sort different types of recyclable materials. Powerful magnets pick up steel cans and optical scanners separate paper and plastic.

At the end of the process, paper, cardboard, plastic, steel and aluminium all get sorted into separate groups and put into large bundles known as bales.

Glass is the only material that does not get baled. It goes into silos to be transported to a glass colour-sorting facility.

Separated materials are then transported to different processing facilities so that they can be prepared for turning into new products.

Once the waste is separated and sorted the recovered material can be processed into new products.

Processing

Plastics

A hard plastics processor will turn the plastics into flakes, wash them and then sort them by colour. The flakes are then sold to plastic manufacturers to become new products, like bottles and containers.

Paper and cardboard

Bales of paper and cardboard are first pulped in a large vat of water to remove any plastic and glue. Next the inks are removed, then the pulp is dried and ironed under heavy rollers to remove any remaining water, and to flatten it into new paper.

Glass

Glass is crushed and melted into a new product called 'cullet', which is often sent to another plant to remove any contaminants. The clean cullets are then crushed further and melted in a furnace. The molten glass is then poured into moulds to become new jars, bottles and fibreglass.

Fun fact

Glass does not degrade through the recycling process, so it can be recycled again and again.

These images appear larger in the gallery box

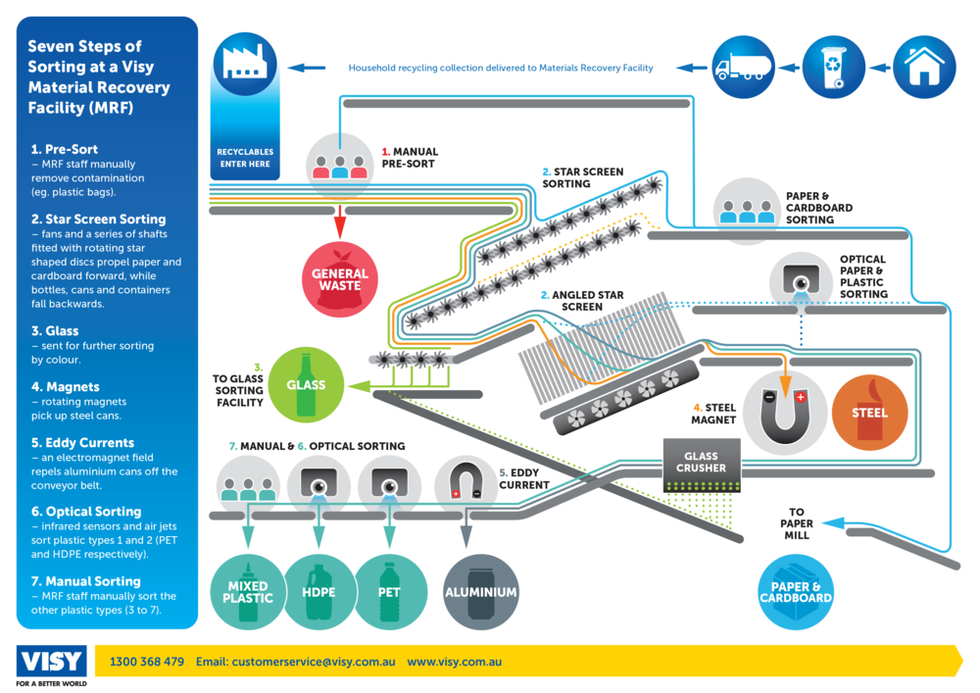

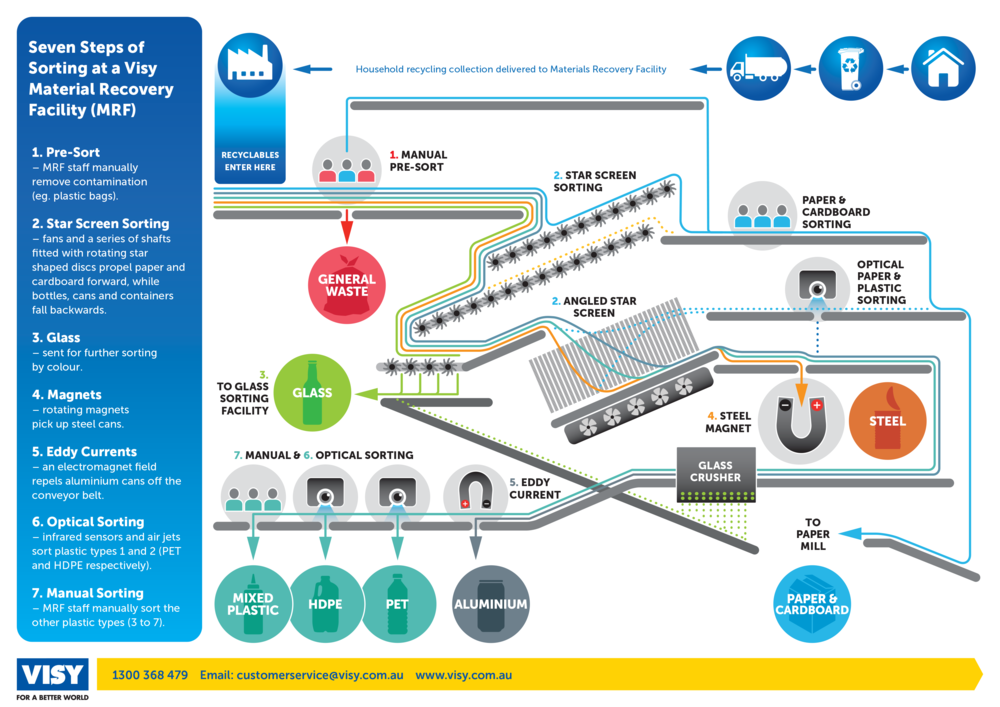

Seven steps of sorting at a Visy Material Recovery Facility (MRF)

- Pre-sort – MRF staff manually remove contaminates from recycling, such as plastic bags, as it travels on the conveying belts.

- Star screen sorting – fans and a series of shafts fitted with rotating star shaped discs propel recycling to the appropriate sorting area. Cardboard and paper is then sorted manually and sent to the paper mill.

- Glass is further sorted by colour and then transferred to a glass sorting facility. Glass that slips through this area is crushed and sent to the glass sorting

- Rotating magnates remove any steel cans.

- Eddy Currents is an electromagnet field that replays aluminium cans off the conveyor belt.

- Optical sorting – inferred sensors and air jets sort soft plastics type 1(PEAT) and type 2 (HDPE) and separate these from the rest.

- Manual sorting – MRF staff manually sort the other plastic types (types 3 to 7).